We take your privacy very seriously, please agree to all cookies used when you visit our website. More information about the processing of personal data could be found inPrivacy Policy

With the growing demand and complexity of driver chips for new energy vehicles and industrial control, developers need to consider more diversified scenarios and more detailed technical points in chip design. Click the video below to learn how to choose the appropriate chip in system development from the three typical application scenarios of "three-phase inverter power drive", "on-board charger electronic lock" and "PLC digital output” based on the latest intelligent driver chips launched by NOVOSENSE, so as to improve the overall performance of the system.

Overview of driver chips selection scheme

For power devices, motors and relays, NOVOSENSE provides two types of driver chips, namely, "grid driver" and "motor driver".

Grid driver chips

NOVOSENSE grid drivers are mainly used to control external IGBT, Mos tube, third-generation semiconductor SiC and other applications. In terms of "whether there is an isolated band integrated in the chip", the grid driver of NOVOSENSE is further divided into grid non-isolated driver chips and grid isolated driver chips.

1) Grid non-isolated driver

NOVOSENSE NSD1025x is used for communication power and PV micro inverter applications, with driving current of ±5 amps and various packages, which is commonly used for double low side control, and is available in the driving mode of voltage-type transformer.

The NOVOSENSE NSD1624 can support withstand voltage of 600V, and realize high voltage of up to 1200V with the company's unique method of "using basic isolation to achieve top tube isolation". Compared with other 600V or 1200V half-bridge drive solutions on the market that adopt high voltage process, NOVOSENSE adopts isolation process for the chips for higher anti-interference ability.

2) Grid isolated driver

With excellent performance in the communication power supply and vehicle market, NOVOSENSE NSi6602 dual-channel half-bridge driver can realize half-bridge control, and provide an isolation belt, which is especially suitable for CLLC-DCDC architecture of SiC and Mos tubes.

In terms of single channel isolation driver, NOVOSENSE provides two products, namely, voltage-type input and current-type input. Voltage-type input NSi6601 mainly relies on CMOS logic for output and driver control, which integrates Miller clamp function for SiC driver; Current-type input NSi6801 is mainly used for optocoupler input replacement, which simulates the optocoupler current-type input, and customers can easily replace an optocoupler-type product without changing the PCB board.

Since 2022, NOVOSENSE has also launched many new isolation drivers, upgrading from the previous drivers with driving current of 4-5 amp to intelligent isolation drivers NSi6611 and NSi6651 of ±10 amp, which integrate complete safety lock plate and protection, as well as Miller clamp, overcurrent protection and other functions.

For current-type isolation driver, NOVOSENSE launched the latest NSi68515 series of intelligent isolation driver with current-type input mode, which can be compatible with many general optocoupler intelligent driver solutions on the market, with such functions as Miller clamp, safety lock plate and protection, and UVLO protection.

Motor driver chips

NOVOSENSE adopts BCD process to integrate Mos tube inside the chip, which can help customers save PCB size, and provide a total solution for customers.

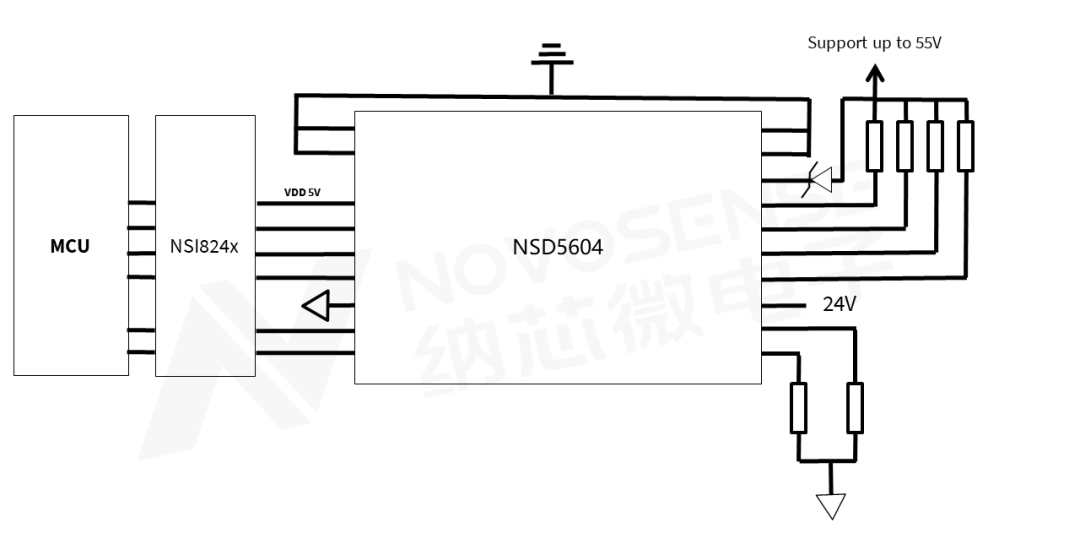

For OBC electronic lock applications, NOVOSENSE has developed a DC brush motor driver NSD731x, which is mainly used for charging guns. For the PLC market, NOVOSENSE NSD5604 multi-channel low side driver can be used to drive relays, providing different resistive and inductive loads.

Application of driver chips

Three-phase inverter power driver scheme

A typical application scheme for onboard inverter three-phase permanent magnet synchronous motor usually involves the detection of interface, MCU/DSP control, flyback power supply, current loop control, temperature and voltage, and it is very important to use intelligent isolation drivers when driving IGBT or SiC power tube. If the drive object is SiC, the drive frequency needs to reach 20-30K. In addition, the SiC has higher requirements for overcurrent, clamp, and conduction protection.

To meet the above requirements, NSi6611 and NSi6651 voltage-type intelligent isolation driver series are launched by NOVOSENSE in different packages, which can support the temperature range certified by automotive-qualified Grade 1 of AEC-Q100. The series adopts the NOVOSENSE-featured dual capacitance isolation technology, with isolation voltage level of up to 5.7kV (average RMS voltage); Higher driving voltages can better match SiC usage scenarios. In addition, the series supports 10-amp rail-to-rail output, matches various Mos, IGBT or SiC tubes, and supports drive frequency to be upgraded to 20-30K; A transmission delay of 80 nanoseconds ensures dead drive in a variety of electric drivers and even power applications in high frequency usage scenarios, and enables a better match between drive performance and software.

Onboard charger electronic lock

According to China’s national standard requirements, all OBCs of above 3.3kW need to be equipped with electronic lock. This means that all OBCs of 6.6kW or higher need to be equipped with an electronic lock to ensure the stability of the OBC when plugged in. NOVOSENSE has developed a motor-driven product that provides electronic locking for the OBC when plugged in. The current peak current on the market is 3.5 amps and the average current is below 1.5 amps.

NOVOSENSE specifically launched the NSD7312-Q1 automotive-qualified chips to meet requirements on voltage, current and RDS(ON) related to the on-board system. In addition, the product also has current modulation function, using duty ratio modulation mode to control the current at a constant current value, and provides power supply protection, undervoltage protection and thermal protection. The tester conducted short-circuit test on the product at 36V, and there was no damages to the chips.

PLC digital output

Typical PLC usage scenarios are often labeled in the instruction manual. If the low-side mode is used, the chips require the optocoupler data transmission function, which can drive the peripheral load by relay-independent Mos or integrated power-level Mos. Load power is sometimes accessed from outside, with a nominal input voltage of 24V and a maximum of 30V. This means that, if you want to a solution to achieve the PLC digital output of all functional integration, you need a low side driver chips with clamp protection, and it is better to support parallel IO port or SPI serial port input; IO input is often used in high-speed solutions, and SPI is often seen in low speed solutions.

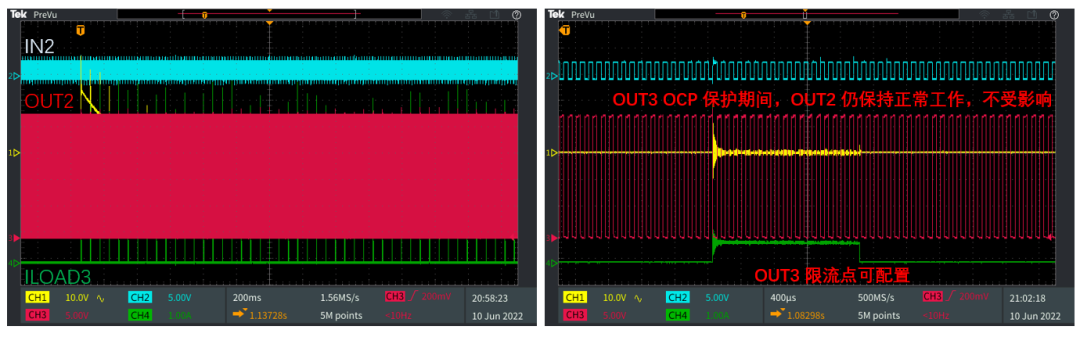

For industrial PLC and motion control, NOVOSENSE has developed a low-side driver NSD5604, which has four-channel low side, and integrates the clamp function of quick shutdown, as well as thermal protection and current limiting protection, and meets the parameter requirements of typical PLC.

- Single-channel independent current limiting protection ensures recovery of short circuit to ground

-Current limits are configurable with fast attenuation to support capacitive and inductive loads

Sample application

For sample application or order, please email to sales@www.sunseasb.com, or call 0086-512-62601802-810.

Thank you for your inquiry.

Please provide the following information and we will contact you as soon as possible, thank you.